未選択

-

[PR]

×

[PR]上記の広告は3ヶ月以上新規記事投稿のないブログに表示されています。新しい記事を書く事で広告が消えます。

-

The Shortcoming of Traditional Laser

As the next generation of display technology, laser display is also subject to the scientific and technological community, the business community of common concern. Compared with the traditional display technology, laser display from the high brightness, clarity, color gamut, color saturation, life and other aspects have a leading edge, highly industrial prospects; many Chinese companies have set off a green laser pointer TV hot, related products Has been listed. From the root, white light laser light source research and development, is the fundamental premise of white laser applications.

The laser is produced by the expansion of the stimulated emission, with good monochromaticity, spatial coherence and temporal coherence, good directionality and high brightness. These four characteristics of the laser show that the laser has a high coherent light intensity in a large coherent volume. Coherence is an important feature of the laser. Conventional laser and white laser, we exclude monochrome (because the white light is not monochromatic), all the laser must have good coherence, direction and high brightness characteristics, can be called laser.

John Ballato focuses on the improvement of light performance, he is looking for fiber materials that will not reduce the blue laser pointer. Has been manufactured to meet the basic performance requirements of the fiber, follow-up will continue to optimize to meet the next generation of high-power laser system requirements. And Lin Zhu is more focused on improving the efficiency of laser pumping, and thus create a strong direction of the laser beam. Although their projects are carried out separately, but for the laser power boost are actively trying. This will also promote the application of high-power lasers, whether in the military or in the industrial sector.

In addition to the above methods, photonic crystal fiber white light lasers can also produce high-power, broadband and ultra continuous white light lasers. Its white light laser is mainly used in the field of photocurrent microscopy, nano photonics, fluorescence spectroscopy and imaging, super-resolution imaging, optical coherence tomography and many other fields. The characteristics of traditional laser not with white light laser, the shortcoming of traditional laser; change and development of white light laser source can bring more fields, and produce new scientific fields, as well as new applications; therefore, it will inevitably become the object of many scientists of the chase.

Due to the laser generated laser restrictions, resulting in a good 10000mw laser monochrome characteristics, but it has become a laser in the field of application of the short board; laser can not produce any wavelength of the laser, can not produce supercontinuum, ultra-wideband laser The In the field of laser applications, people have different requirements for the frequency (or wavelength) of the laser, and this time with the help of nonlinear crystals. But many bands of laser still can not be created.

PR -

Laser Plasma Accelerators

In this latest work, John Doyle and colleagues at Harvard University have now cooled the three-atom hydroxyl strontium molecules, named after the Greek hero Sisyphus, who was forced to push a boulder onto the top of the hill, Roll down and then often resemble this work forever. Sisyphus cooling process is the molecule through the "climb" by the laser standing waves generated by the potential energy loss of kinetic energy process.

The accelerator works by projecting a high-energy, high-brightness burning laser pointer beam onto a thin metal foil target with an area of only a few square microns. "The energy of the laser pulse is large and the energy of the generated electromagnetic field is even more than an order of magnitude greater than the coulomb force inside the atom," Hidding explains. "The metal foil target is therefore instantaneously converted to a plasma." The plasma particles are strongly excited by the laser and other plasma field acceleration, the degree of acceleration depends on the initial position of the particle, this process can produce huge energy.

With the laser to the atomic gas cooled to ultra-low temperature, first appeared in the late 1970s, completely changed the material quantum state of the study. The first Bose-Einstein condensate was manufactured in the laboratory in 1995. The first Fermi-Dirac condensate was created in 2003 as two important milestones for this technology. The technique relies on the fact that the photon carries a small amount of momentum, and under certain conditions, the atomic reabsorption and re-emission of the photon can reduce its random motion and thus reduce its temperature.

Space radiation in outer space is replicated in the laboratory. Scientists use 5000mw laser pointer plasma accelerators to replicate high-energy particle radiation around the Earth. The study can help scientists to study the impact of space exploration on human beings, and for the development of satellite and rocket equipment to provide a strong guarantee.Space radiation is a major obstacle to human exploration of the solar system. High-energy ionized particles of the sun and deep space are extremely dangerous to human health, and they can penetrate directly through the skin and deposit energy, causing irreversible damage to cells and DNA. In addition, space radiation can cause serious damage to satellite equipment.

-

Glass Laser Engraving

The glass is easily broken during the engraving process, so the glass engraving must be very careful. For different types of glass, lead content is different, its engraving methods are not the same. With the increase in lead content, glass hardness, high temperature viscosity and so on, the glass is also more easily broken. Ordinary glass is usually easier to carve than crystal glass, because the crystal glass lead content is high, hardness viscosity decreases, increasing the difficulty of brightest laser pointer engraving. Glass laser engraving process: When the laser beam touches the glass surface, the glass surface heats up, the glass molecules fly. If the glass can not be cooled down, the heat generated by the potholes will be bigger and bigger, the final carving effect will be as bad as mud.

At present, there are many kinds of laser technology for glass cutting, and these technologies are implemented in a variety of ways. However, the main advantages of all these glass laser cutting techniques are similar. First, all laser cutting methods use non-contact machining, which greatly avoids the problem of fine cracks and debris. In addition, the residual stress left by the blue laser pointer cutting method in the glass is very small (the residual stresses of the different cutting methods are different), and thus the cutting edges are of higher strength. This is very important, if the residual stress is too large, then even in the center of the glass force, often also lead to the edge of the glass rupture. Therefore, compared with the use of mechanical cutting glass, laser cutting glass can withstand the force to one to two times larger.

Laser cutting can also reduce the number of process steps due to the need for (or no) the need for subsequent cleaning or grinding stages. Thus, although the cost of capital for laser cutting workstations is higher than that of mechanical systems, the total investment in laser cutting is lower than that of mechanical processing systems because no additional grinders are required. Due to the reduced demand for post-processing and cleaning work, the best burning laser pointer cutting method is more environmentally friendly than the mechanical method and consumes less water (or does not require water at all). Finally, some laser cutting methods support glass curve cutting. Today, the demand for curve cutting is growing, especially in the cell phone manufacturing industry, manufacturers want to produce more complex geometric shapes of the screen, including punching material to accommodate buttons, control keys, LED and camera lens.

CO2 and CO laser source processing glass are in the principle of local intensive heating. Specifically, all the glass is easily absorbed by the CO2 laser at a wavelength of 10.6 microns, so the focused laser beam can quickly heat the glass surface or near surface area. In order to achieve the cutting effect, the glass needs to be translated relative to the laser beam and the glass is rapidly cooled by the spray or jet above the glass. The resulting thermal shock causes the glass to form a continuous slit. If the glass is thinner, the slit can penetrate the substrate completely, thus completing the cutting directly, which is called "overall cutting". If the glass is thick, then you need an additional laser or mechanical breaking link to complete the cut, called "laser scribing."

The overall processing of the CO 1000mw laser pointer is roughly the same as above. However, the glass to the CO laser output 5 micron to 6 micron laser absorption rate is significantly reduced, which makes the laser irradiation of large pieces of material can penetrate deeper. Therefore, the heat can be directly into the large pieces of glass, without having to rely on the surface from the spread. Tests conducted by related companies show that this can further reduce the residual stress than using CO2 lasers, thereby increasing the strength of the cut workpiece while allowing the manufacturer to expand the processing interval. There is also an attractive advantage for CO lasers to support curve cutting. CO2 lasers are often confined to cutting the glass in a straight line because the circular output beam must be remodeled into slender light in order to better diffuse the high temperature produced on the surface. In contrast, the low absorption rate of CO lasers allows it to use circular beams directly without adverse thermal effects. In addition, CO lasers also support cutting chemical tempered glass.

The laser ablation of the glass processing mechanism is completely different from the CO2 and CO lasers that form slits by thermal shock. Laser ablation The way to achieve scribing is to actually remove the material by precision ablation. Abnormalization is achieved when a sufficiently large 300mw laser pointer is applied to excite the nonlinear absorption in the glass. In this way, the material can be removed by local intensive heating (hot ablation) or by direct destruction of interatomic chemical bonds (light ablation) through extremely high peak power.

-

Laser Processing Technology

The development of miniaturized, low-cost laser particle accelerators is the goal that scientists have always dreamed of. The ultra-short laser-driven tail-wave field accelerator has an ultra-high acceleration gradient of three orders of magnitude higher than that of a conventional RF accelerator, providing a new way to achieve miniaturization of high-energy particle accelerators, Radiation devices, free electron lasers and high-energy physics research will also have far-reaching impact.

Protons and other positive ions have a wide range of applications, including particle physics, materials processing and medical aspects. For example, proton beam therapy can be used to destroy some cancerous tumors at minimal damage to surrounding tissue. However, the actual use of protons and ion beams is subject to constraints that require a larger and expensive particle accelerator to produce a high quality beam source. By controlling the polarization of the incident 1mw laser pointer, the quality of the laser accelerating the proton beam can be improved, and the researchers have found this conclusion. This discovery can help physicists create compact proton beam sources for medical, lithography, and even astrophysics.

With the further study of the interaction between lasers and materials, laser processing technology will also be widely used in flexible manufacturing systems. The flexibility of the laser processing system mainly refers to the laser processing head can be flexible to guide the laser beam to reach the parts to be processed position. Dimensional laser processing, high power laser pointer three-dimensional processing is the future direction of the direction of development of laser processing, in order to achieve the flexibility of laser processing, three-dimensional laser must be in the direction of the laser processing machine, Using motion optical system. High-power three-dimensional YAG laser processing system is usually used robot (or robot) with optical fiber for beam transmission, by the robot holding the laser head to complete a variety of movement, the laser is transmitted through the optical fiber to the laser processing head, to reach the workpiece surface, which In the processing system, the beam transmission and focusing characteristics are not affected by the machining position.

In a separate experiment, the researchers irradiated the aluminum foil line with laser pulses, i.e., elliptically polarized light and circularly polarized light from the Gemini burning laser pointer. The pattern of the protons of different energies is significantly different: for example, in all polarized states, low-energy protons are concentrated in the center, but elliptically polarized and circularly polarized light are more compact in propagation than linearly polarized light. The high-energy protons produced by linearly polarized light are called double lobes, while circular and elliptically polarized light form a circular density distribution. The experimental observation of the pattern closely matches the computer simulation conclusion, and the existence of small deviations can be fully understood as experimental defects, the researchers explained.

The use of laser processing, not only processing speed, high efficiency, low cost, and to avoid the mold or tool replacement, shorten the production preparation time cycle. Easy to achieve continuous processing, laser beam transposition time is short, improve the production efficiency. Can be a variety of workpiece alternately installed. When a workpiece is machined, the finished parts can be removed and the workpiece to be machined is installed to achieve parallel machining, reduce installation time and increase the red laser pointer processing time. The laser itself is a relatively simple and easy to control device, if it produces the beam into a very fine light beam, you can cut; defocus can be welded; and then defocus a little, can be heat treatment.

The laser beam is driven by direct drive and guide. The laser can be used for rotation, tilt, up and down movement around the movement, the workpiece can be processed on the vertical surface and complex surface; and direct drive without air, high precision. The combination of 5mw green laser control and robots, with the robot to move or multi-axis way to flip the parts under the beam, can be processed with some traditional methods of processing more difficult parts. Take the multi-level rapid response of the anti-collision measures, beam guide device contact the workpiece, the movement system immediately shut down, so that the system is not destroyed, to avoid the expensive maintenance; collision can quickly and simply resume work, reducing the collision caused by downtime Time, improve the processing efficiency and reliability of the laser system.

-

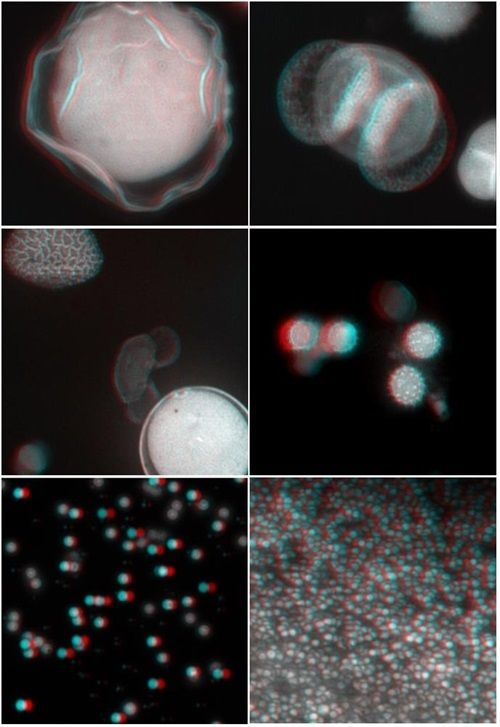

Two - photon Excited Laser Scanning Real - time Stereomicroscope

Recently, the State Key Laboratory of Transient Optics and Photonics, the Institute of Optics and Precision Mechanics, Xi'an Institute of Optics and Fine Mechanics, Chinese Academy of Sciences (hereinafter referred to as "Transient Room") has successfully developed a two-photon excited strongest laser pointer scanning real-time stereomicroscope. Microscopic methods and high-resolution two-photon excited laser scanning fluorescence microscopy combine to achieve high-speed stereoscopic imaging of three-dimensional fluorescent samples and are authorized for national invention patents.

Contemporary life science research has made increasing demands for optical microscopy - higher spatial resolution, greater imaging depth, and faster imaging speed. Especially for biological in vivo microsurgery, the scattering of light from biological tissue greatly increases the noise, which seriously affects the spatial resolution and imaging depth. In order to improve the imaging depth, two-photon excited 300mw green laser scanning fluorescence microscopy technology has been widely used in the field of nerve imaging since the 1990s, but its imaging method of point-by-point scanning has seriously restricted the imaging speed. Because the depth of view of the high-resolution optical microscope is very small, it is necessary to complete the three-dimensional imaging of the sample, usually need dozens of layers or even hundreds of layers of two-dimensional image of the superposition of reconstruction, image acquisition and processing generally takes several minutes or even tens of minutes Fast and real-time acquisition and display of three-dimensional images is very difficult.

Transient chamber super-resolution imaging team under the leadership of the researchers Yao Baoli and Ye Tong, the binocular vision principle and the Bessel beam to produce the expansion focal field, proposed by the four galvanometer composed of burning lasers for sale beam stereoscopic scanning device, The control of the three positions of the Beerle beam and the inclination of the Bezier beam is achieved, which breaks the limitation of the traditional laser scanning with only two degrees of freedom. By means of the optimal design and control of the three-dimensional scanning device, the three-degree-of-freedom fast scanning of the Bezier beam can be realized, and the double-view angle can be switched on the order of milliseconds to solve the double- Optical path at the same time imaging technology, for the first time to achieve a real-time laser scanning based on dual-view stereoscopic imaging and display system. The system can be three-dimensional dynamic imaging of the sample and real-time binocular stereoscopic observation, the three-dimensional imaging speed than the traditional point-by-point scanning method increased by one to two orders of magnitude. The two-photon 200mw green laser stereomicroscope system provides a new observation tool for 3D real-time imaging and display of living organisms.

"It allows us to view the dynamic 3D microcosm in real time like watching a three-dimensional movie without the need for light slicing without the need for time-consuming three-dimensional image reconstruction." Yang Yanlong so summarized the characteristics of this system, he is responsible for the design and completion of the three Scanning and imaging the key parts of the display. "Binocular vision imaging is a very efficient way to obtain three-dimensional information, but the existing 100mw laser pointer stereomicroscope, spatial resolution and depth of field are mutually constrained, and we use three degrees of freedom to scan the Bezier beam for nonlinear fluorescence excitation to break through this limit."

This research has been carried out from the basic principle verification, the key technological breakthrough to the prototype prototype, and has experienced all aspects of basic research to application integration under the support of the "100 people program" and the National Natural Science Foundation of the Chinese Academy of Sciences. At present, the research group is working with relevant scientific research institutions at home and abroad to carry out biomedical application of 30mw laser pointer cooperative research, as soon as possible to apply the technology to the biological in vivo three-dimensional rapid imaging and display areas.

http://prsync.com/htl/laser-technology-1437182/

http://laserman123.diarynote.jp/201702171759591624/

www.freePRnow.com/pr/global-laser-industry-usher-in-new-opportunities