未選択

-

[PR]

×

[PR]上記の広告は3ヶ月以上新規記事投稿のないブログに表示されています。新しい記事を書く事で広告が消えます。

-

How to achieve laser + intelligent manufacturing?

What is the specific smart manufacturing, 100 companies may have a hundred solutions, but the core should be the concept of further sublimation of automation, until the flexible and intelligent. In the field of mechanical equipment, high power laser pointer processing equipment more easily automated integration, is the core of intelligent manufacturing equipment. Therefore, the laser and intelligent manufacturing how to perfect combination, is the future manufacturing upgrade important factor.

As the main provider of laser equipment, Han's laser in the field of intelligent manufacturing has long been the layout of its robot, machine vision, sensors, automation equipment and other intelligent, automated technology-related reserves of resources. Recently, Han's Laser Intelligent Equipment Group in Guangdong Province, Shenzhen, led the industry and more than the laser industry experts witnessed the opening, but also taken a step in the field of intelligent manufacturing.

In the specific application areas, Han's laser power battery manufacturing in the area of key layout. In the subsidy, limit number, environmental pressure and other factors under the influence of the electric car industry is booming. Its power source batteries, battery modules are the core components of electric vehicles manufacturing process to be introduced urgently, cheap laser pointer processing technology in this area promising. Han's vice president of huangxiang hu has said on many occasions, very optimistic about the future of laser technology in the field of power battery manufacturing prospects. According to Huang Xianghu introduction, Han's laser to build a new energy lithium equipment, closed-loop ecosystem.

At the beginning of 2016, Han's Laser Strategic Investment Holdings Dongguan Junzhuo Automation Technology Co., Ltd., which opened the Han officially entered the pack and module automation and equipment in the field of prelude. Subsequently, with the Shenzhen Municipal Science and Technology Co., Ltd. signed an agreement to invest in the acquisition of lithium batteries to achieve the welding and injection of seamless link. Since then, Han's Laser and Dongguan Zhuang Ling Automation Technology Co., Ltd. signed a merger agreement, which marks its entry into the field of lithium battery coating. In recent days, Han's new acquisition of Jin Fan Jin-fan laser, and further open up the power battery single, double coating equipment.

As a result, Han's laser successfully created a complete set of intelligent battery manufacturing solutions, but also for the green laser pointer technology into the field of intelligent manufacturing provides a good reference sample.

PR -

The Shape of the Photon Affects the Interaction of Light and Matter

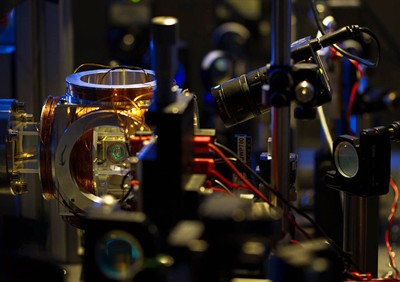

Scientists at the National Center for Quantum Technology (CQT) at the National University of Singapore have revealed that the shape of a photon can affect its absorption by a single atom. They say the finding is significant, suggesting that the photon's energy, or 5mw laser pointer wavelength, is no longer the only factor determining photonic behavior.

CQT chief scientist Christian Kurtsiefer and his research team have mastered how to accurately control the photon shape. "We usually do not think that photons will spread in space and time, and have a certain shape, but the photons we use in our experiments are four meters long," he commented.

The results were published in the November 29 issue of Nature Communications, using rubidium atoms and infrared photons. Each emitting a photon to a single alkali metal atom. "Our experiments study the most fundamental interaction of light and matter," commented Victor Leong, a Ph.D. student who participated in the study.

It takes 13 nanoseconds for a 4-meter photon to pass through such atoms. Whenever a photon passes through an atom, the team looks at whether or not the atom is excited. By recording the excitation time, the researchers can get the photon atomic absorption of the probability of time-varying relationship.

Two kinds of photons with different shapes of brightness increase and attenuation are studied. Hundreds of millions of 200mw laser pointer measurements lasting more than 1500 hours show that for both types of photons they are just over 4% absorbed by rubidium atoms. However, if the time scale from nanoseconds, each time the photon absorption probability and the shape of the photon.

CQT's team found that if the photon reaches the atom, the photon intensity after the first weak and strong, then the peak atomic excitation probability than the photon brightness of the first strong case of more than 50% higher than weak.

Researchers envisioned atoms more likely to absorb energy-boosting photons, explains Matthias Steiner, co-author of the paper, explaining that "the natural process of releasing photons by stimulated atomic decay causes this phenomenon. Atoms release an attenuated photon, In turn, imagine that the form of the equation does not change and that atoms will naturally encounter photons with increased brightness, and that the photons we choose to shape are inspired by the time - reversal symmetry of quantum mechanics.

The research team believes that their work helps to understand the use of 400mw laser pointer light and material interaction technology, "such as quantum communication, sensors, computing and other quantum technology involved in the process, usually need to use information into the photon atoms. "In order to design reliable quantum devices, scientists need to control this interaction, and you can use it only if you understand the interaction," says Alessandro Cerè, co-author of the paper.

The main conclusions are as follows: "We found that the process of light scattering is related to the photon's envelope.With the exponential decay of the envelope shape of the photon with time exponentially increasing with time, the envelope shape of the photon can more effectively excite the atoms.Using the exponential rise Shape of the photon excited atoms, which in a narrower time interval to produce a higher peak excitation probability of such synchronization will help the quantum communication network connection.

-

Lidar is a Robot's Eye and Ear

For owners, radar ranging is not strange. When driving at high speed, the radar range allows the car to keep the distance between the car and the car, the car will automatically move forward, the owner can not step on the accelerator. Of course, the direction must be controlled by the owner. Moreover, the use of radar range, the vehicle can also detect the front of the vehicle, and maintain their own distance; when the car is too close, it will automatically reduce the speed. So it seems that, although the radar range does not liberate the driver's hands, but at least one foot Liberation (foot on the accelerator), it can be regarded as a pioneer unmanned. However, radar range is not just used on the car. Lidar is so good, why do robots rarely use 300mw laser pointer radar to avoid obstacles?

The radar is "radal English" abbreviation, radio method discovery state parameters of the target and determine their space positions, and the distance of the target, ask and speed is mainly composed of antenna, transmitter and receiver (including signal processor) and a display part. If it is a bit more popular, the radar is similar to the eyes or ears, of course, it is no longer a masterpiece of nature. The principle of measuring distance is as follows: measuring the time difference between the transmitted pulse and the echo pulse, because the electromagnetic wave travels at the speed of light.

There are many kinds of radar, and the classification method is very complicated. Military radar. Can usually be classified according to the purpose of radar, such as early warning radar, search radar warning radar, command, artillery radar, radar altimeter, battlefield surveillance radar, airborne radar, radio altimeter, radar fuze, weather radar, navigation, navigation and collision avoidance radar control radar and IFF radar etc..

According to the classification of radar signal, pulse radar, continuous wave radar, pulse compression radar and frequency agile radar; according to the classification of angle tracking mode, a single pulse radar, conical scan radar and concealed conical scanning radar; target classification according to the parameter measurement, measurement of two coordinate radar, Gao Lei, three coordinate the enemy radar and recognition of radar, multi station radar; radar frequency according to points, can be divided into radar, microwave radar, millimeter wave radar and 5mw laser pointer radar. The radar has a day and night can detect, block and not affected by fog, clouds and rain, has the characteristics of all-weather, all day long time, advantages, and a certain degree of penetration so that not only become the military indispensable electronic equipment, but also widely used in other fields, such as weather forecasting, resource exploration, environment monitoring, even related to scientific research, such as research objects, atmospheric physics, ionospheric structure research.

Now, radar ranging is also used in the industry of the most current - robotics. So, what is the role of radar in the field of robotics? At present, how to apply the rate?

The application of radar in the navigation of mobile robot is more and more. This is mainly due to the many advantages of the laser radar range measurement technology, compared with other distance sensors, it can take into account both the accuracy and speed requirements. Work in the infrared and visible light, green laser pointer beam radar work called laser radar is a radar system to transmit the laser beam to detect the target position and velocity characteristics, laser radar provides a good method for robot navigation.

Some robots are free to walk, they use a remote control or pre programmed. The robot's "true freedom walk" should be able to identify the obstacle, by turning and stop the realization of active avoidance, and achieve independent route planning, laser radar is an important method to solve the bottleneck of the popularity of the robot obstacle.

In order for a robot to walk, one must first see it - in addition to the algorithm, as well as the important hardware. Laser radar allows the robot to emit burning laser pointer target detection signal, and then received back from the reflected and transmitted signals are compared for proper treatment, information about the target, such as target distance, azimuth, altitude, speed, attitude and even shape parameters. In fact, the robot is positioning itself, positioning objects, as well as map building. A hands-on ability of electronic production, spent half a year to create a full range of radar attack robot". The use of ultrasonic ranging radar, not only to identify where the master's shoes, but also to the owner of the shoes.

At present, the application area of laser radar is the sweeping robot, which is mainly to achieve the purpose of obstacle avoidance and automatic path planning. Now a number of entry-level sweeping robot, in fact, the process is relatively simple sweep, mostly only with the ability to clean the N font, including the coverage area is difficult to assess the coverage. According to the sweeping robot experts said that the fundamental reason is that they can not see, can not walk freely. At this time, the laser radar has played the role of sweeping robot eyes, so that it can achieve the purpose of cleaning.

Laser radar is so good, why is the market rarely see the use of high power laser pointer radar robot?

At present, in the world, in addition to some Chinese enterprises, only a few companies, such as Japan and Germany have the ability to produce laser radar, but its price is not low. General service robots can not afford such an expensive component. So expensive is also a reason, the general laser radar technology in the development of a certain degree of difficulty. Technically, the precision is good and achieve millimeter accuracy is not easy, want to achieve this precision, a big problem: the process precision, to achieve long-distance mm level accuracy of optical measurement technology and in fact are required. In fact, the price of speed, traditional laser rangefinder is not expensive, Taobao may be a few hundred dollars could buy one, but its measurement speed is very slow, it may take a few seconds to complete, and the need to complete the measurement of 100mw laser pointer radar, thousands of thousands of times in a second. So the price of traditional laser radar is also very expensive.

-

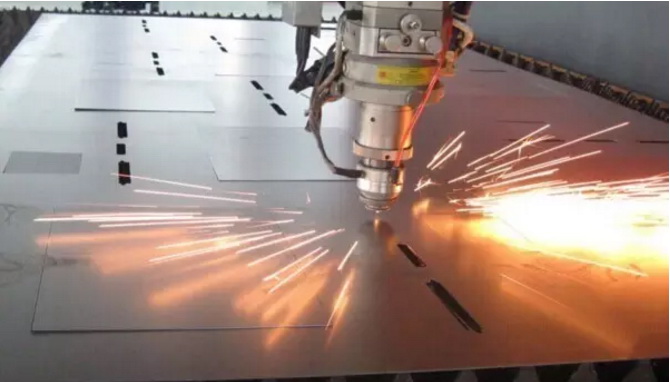

What are the performance advantages of fiber laser cutting machine?

Fiber laser cutting machine is in recent years in the international market newly invented a new type of cutting machine, the cutting machine products in cutting speed, or in the mechanical volume have absolute advantage, today we mainly explain the main advantages of this cutting machine is reflected in what areas.

The new fiber laser cutting machine adopts the principle of cutting is a kind of high performance 300mw laser pointer cutter, laser ray emitted from the numerous high performance and high energy in the process of laser cutting, laser radiation generated by these huge energy, you can instantly cut surface evaporation, so it can easily be very hard interface removed. At present, this technology still belongs to a kind of cutting technology is the most advanced, without any other cutting process can surpass it, and this speed cutting process in cutting process is very fast, you can instantly be very thick steel plate and easy cutting, cutting accuracy is very accurate, the cross section of the cutting precision can reach several millimeters can fully meet the demand, cutting some high requirements.

The new fiber laser cutting machine adopts the principle of cutting is a kind of high performance laser cutter, laser ray emitted from the numerous high performance and high energy in the process of laser cutting, 50mw laser pointer radiation generated by these huge energy, you can instantly cut surface evaporation, so it can easily be very hard interface removed. At present, this technology still belongs to a kind of cutting technology is the most advanced, without any other cutting process can surpass it, and this speed cutting process in cutting process is very fast, you can instantly be very thick steel plate and easy cutting, cutting accuracy is very accurate, the cross section of the cutting precision can reach several millimeters can fully meet the demand, cutting some high requirements.

In the process we use fiber laser cutting machine, spread all the dissemination of information and energy is transmitted through optical fiber transmission, in this way the biggest advantage is to save a lot of manpower, light path any leakage phenomenon can not be generated in the transmission process. And before using the device without any adjustment of the light path, you can easily transfer energy to the laser.

The core components of the 5mw laser pointer cutter it is only one, that is the laser, and laser production volume is very small, not like other products of the same type as cutting occupy a lot of space, so that the overall mechanical volume will be reduced a lot, not in mechanical manufacturing or transportation process can reduce a lot of the manpower for us.

-

Laser Rapid Prototyping Technology

The use of laser through the interaction with the material, according to certain requirements of the processing or molding, collectively referred to as light manufacturing. Nearly 20 years, light manufacturing technology has penetrated into the high-tech fields and industries, and began to replace or transform some of the traditional processing industry. In the developed countries of the automotive industry, 50% -70% of the parts is completed by laser processing. Light manufacturing technology to improve the automotive industry R & D and manufacturing level, is playing an increasingly important role.

At present, the light source used in the light manufacturing technology is mainly laser, the high power laser pointer beam has the characteristics of high energy density, high single-palladium and high directivity, which makes the optical manufacturing technology has many advantages over the traditional manufacturing technology. The tool used in this technology is the "laser knife", no tool wear during machining; no effect of cutting force on the workpiece during machining, so the workpiece without cold processing deformation; due to high energy injection processing time, the workpiece heat is small, The laser has good spatial control (direction change, rotation, scanning, etc.) and time control (open) of the laser beam, which can not be processed by the conventional technology. , Off, pulse interval), particularly suitable for automated processing, large-scale manufacturing in the production of high efficiency; laser processing of the object material, shape, size and processing environment are great freedom; low noise, does not produce harmful rays and Residue, the production process of environmental pollution is small; can save molds, shorten product development cycle and reduce development costs; material waste, in large-scale production of low manufacturing costs.

Laser manufacturing, laser drilling, laser marking and laser cutting are the key technologies for light manufacturing. No cutting stress, no cutting burr; high precision, good repeatability, do not damage the surface of the workpiece. The cutting edge is smooth, smooth cutting edge, cutting edge parallelism, no procurement follow-up processing; Laser drilling speed, high efficiency, suitable for large quantities of high-density group of holes processing; green laser pointer drilling can obtain a large aspect ratio can be hard, brittle, soft and other materials for processing, and even in the Difficult to process materials on the inclined plane processing holes; laser drilling process clean, non-polluting. Laser marking is a non-contact marking, fast, easy to wear mark, laser marking machine and very easy to combine with the assembly line. Laser cutting is similar to machining in a process of milling, it is the use of focused laser beam to cut the material layer by layer.

Laser welding is the use of high-intensity laser beam will be welded to the local melting temperature of molten metal fusion welded joints made of the process. Can weld high-melting point metal, non-metal, composite materials and other special materials, but also to achieve dissimilar materials and special welding structure welding; weld with "self-purification" effect, high quality weld; can be accurate welding, generally do not need Filling the metal; through the light guide system so that the laser beam and a number of devices constitute a flexible processing system, welding a high degree of automation, high production efficiency; high-energy beam welding, laser welding is characterized by the largest vacuum chamber does not produce x-ray .

Laser surface hardening is divided into two laser pointer hardening and laser melting hardening. Laser phase transformation hardening, also known as laser quenching, it is a high-energy laser beam rapid scanning of the workpiece, so that the surface temperature of the irradiated metal or alloy to a very fast rate to the point above the laser beam from the irradiated parts, Due to heat conduction, in the cold state of the matrix to rapidly cooling and self-quenching, get a smaller layer of hardened layer, the hardness is generally higher than the conventional quenching hardness; laser melting hardening process similar to the previous process, the difference is that the laser The surface of the material heating temperature is higher, the final part of the surface to form a layer of tissue flame hardening layer. Laser welding is the use of high-energy laser beam irradiation of the cladding material, with the substrate surface layer with rapid melting, forming with the substrate metallurgy with completely different composition and performance of the alloy coating.

Light rapid prototyping technology principle is under the control of the computer, CAD and other parts of the design model and data, the burning laser pointer beam will be forming material layer by layer curing, from the point and line structure parts of the surface (layer), the surface accurate accumulation of three-dimensional Solid model or part of the process. The use of light rapid prototyping technology, can significantly shorten the product development cycle, greatly reduce development costs, can quickly produce products to adapt to market changes, maintain and enhance the competitiveness of products in the market. At the same time, the use of optical rapid prototyping technology is also to achieve concurrent engineering and agile manufacturing effective technical approach.