-

[PR]

×

[PR]上記の広告は3ヶ月以上新規記事投稿のないブログに表示されています。新しい記事を書く事で広告が消えます。

-

Laser Rapid Prototyping Technology

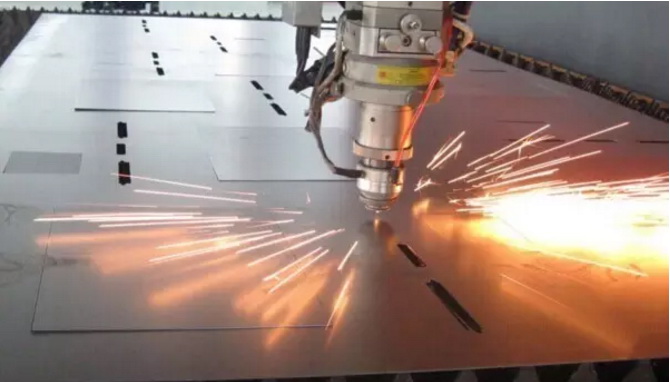

The use of laser through the interaction with the material, according to certain requirements of the processing or molding, collectively referred to as light manufacturing. Nearly 20 years, light manufacturing technology has penetrated into the high-tech fields and industries, and began to replace or transform some of the traditional processing industry. In the developed countries of the automotive industry, 50% -70% of the parts is completed by laser processing. Light manufacturing technology to improve the automotive industry R & D and manufacturing level, is playing an increasingly important role.

At present, the light source used in the light manufacturing technology is mainly laser, the high power laser pointer beam has the characteristics of high energy density, high single-palladium and high directivity, which makes the optical manufacturing technology has many advantages over the traditional manufacturing technology. The tool used in this technology is the "laser knife", no tool wear during machining; no effect of cutting force on the workpiece during machining, so the workpiece without cold processing deformation; due to high energy injection processing time, the workpiece heat is small, The laser has good spatial control (direction change, rotation, scanning, etc.) and time control (open) of the laser beam, which can not be processed by the conventional technology. , Off, pulse interval), particularly suitable for automated processing, large-scale manufacturing in the production of high efficiency; laser processing of the object material, shape, size and processing environment are great freedom; low noise, does not produce harmful rays and Residue, the production process of environmental pollution is small; can save molds, shorten product development cycle and reduce development costs; material waste, in large-scale production of low manufacturing costs.

Laser manufacturing, laser drilling, laser marking and laser cutting are the key technologies for light manufacturing. No cutting stress, no cutting burr; high precision, good repeatability, do not damage the surface of the workpiece. The cutting edge is smooth, smooth cutting edge, cutting edge parallelism, no procurement follow-up processing; Laser drilling speed, high efficiency, suitable for large quantities of high-density group of holes processing; green laser pointer drilling can obtain a large aspect ratio can be hard, brittle, soft and other materials for processing, and even in the Difficult to process materials on the inclined plane processing holes; laser drilling process clean, non-polluting. Laser marking is a non-contact marking, fast, easy to wear mark, laser marking machine and very easy to combine with the assembly line. Laser cutting is similar to machining in a process of milling, it is the use of focused laser beam to cut the material layer by layer.

Laser welding is the use of high-intensity laser beam will be welded to the local melting temperature of molten metal fusion welded joints made of the process. Can weld high-melting point metal, non-metal, composite materials and other special materials, but also to achieve dissimilar materials and special welding structure welding; weld with "self-purification" effect, high quality weld; can be accurate welding, generally do not need Filling the metal; through the light guide system so that the laser beam and a number of devices constitute a flexible processing system, welding a high degree of automation, high production efficiency; high-energy beam welding, laser welding is characterized by the largest vacuum chamber does not produce x-ray .

Laser surface hardening is divided into two laser pointer hardening and laser melting hardening. Laser phase transformation hardening, also known as laser quenching, it is a high-energy laser beam rapid scanning of the workpiece, so that the surface temperature of the irradiated metal or alloy to a very fast rate to the point above the laser beam from the irradiated parts, Due to heat conduction, in the cold state of the matrix to rapidly cooling and self-quenching, get a smaller layer of hardened layer, the hardness is generally higher than the conventional quenching hardness; laser melting hardening process similar to the previous process, the difference is that the laser The surface of the material heating temperature is higher, the final part of the surface to form a layer of tissue flame hardening layer. Laser welding is the use of high-energy laser beam irradiation of the cladding material, with the substrate surface layer with rapid melting, forming with the substrate metallurgy with completely different composition and performance of the alloy coating.

Light rapid prototyping technology principle is under the control of the computer, CAD and other parts of the design model and data, the burning laser pointer beam will be forming material layer by layer curing, from the point and line structure parts of the surface (layer), the surface accurate accumulation of three-dimensional Solid model or part of the process. The use of light rapid prototyping technology, can significantly shorten the product development cycle, greatly reduce development costs, can quickly produce products to adapt to market changes, maintain and enhance the competitiveness of products in the market. At the same time, the use of optical rapid prototyping technology is also to achieve concurrent engineering and agile manufacturing effective technical approach.

PR -

Scientists Have Discovered a New Kind of Soliton Wave

The application of Kerry Vahala in California Institute of Technology scientists led by the discovery of a new soliton, soliton wave behind the wave will follow in other media, like take a ride of other waves and draw energy from other wave. A soliton is a localized wave like a particle: when they travel through space, they keep their shape and shape, not like the other waves. They were first proposed in 1834 by the Scotland Engineer Scott Russel John, who found that a sudden stop in the union canal between Faure Kirk and Edinburgh formed an unusual wave. Russell tracked the waveform for one to two miles, and pointed out that it retained its shape in the course of travel until it finally lost its trace.

He called his discovery "mobile wave", to the end of this century, this phenomenon is described in mathematics, and ultimately the concept of soliton wave. Under normal circumstances, when the wave is transmitted through space, the wave will dissipate. Throw a stone into a pond, and when they are scattered from the point of impact, the ripples will slowly disappear. And soliton wave. In addition to water waves, solitons can occur in the form of 30000mw laser pointer light waves. Vahala's team studied optical solitons through the micro scale loop circuit called optical micro cavity so that the optical soliton infinite recycling. The application of soliton can be used to create high precision optical clock, and can be used for microwave oscillator, for navigation and radar systems, and many other applications in the scene.

But despite decades of research, a soliton has never been observed in the form of such a dependency is almost parasitic behavior. "In essence, this new soliton is to take on another solitons, in the wake of another soliton. It also siphoned from other soliton energy, so it is self-sufficient. It will eventually grow larger than its parasitic master, "Vahala said he was information Science and technology and professor of applied physics Ted and ginger Jenkins and applied physical sciences and engineering executives of materials science and applied science.

Vahala will this new soliton like pilot fish, is a carnivorous fish shark will swim in the side, they can pick up the pieces from shark food. And in the shark's tail parade, pilot fish reduced their own bodies of water resistance, so they can use less strength to walk. Vahala is published in "Nature Physics" magazine that announced the new types and description of the soliton co-author, known as the "Stokes solitons" ("Stokes", because of technical reasons, namely the soliton energy siphon mechanism) and is a graduate of California Institute of Technology and Yang Qifan Xu for the first time to observe new soliton. Since the soliton can be close to the shape and position of the original soliton, Yang Heyi's initial reaction is to doubt the laboratory instrument failure.

"By observing the signals of two spectrometer, we confirmed that the signal is not an instrument error. Then, we know this is true, and must figure out why a new soliton can occur spontaneously such a situation," Yang said, . Vahala and his team used include laser 3000mw input provides energy solitons microcavities. This energy is not directly determined by the "pilot fish" absorb Stokes soliton Instead, energy is "Shark" soliton consumed. However, Vahala and his team found that the energy is taken away by the pilot fish solitons, which increase in size while the other soliton contraction. "Once we understand the environment needed to produce new solitons, it is actually possible to ensure that our design microcavities formed solitons, and even its nature as an effective wavelength, color, etc.," Yi said.

-

Application of Laser Technology in Automobile

Application of Laser Technology in Automobile

When it comes to laser pointer technology applications in the car, we perhaps laser welding, laser cutting and laser marking technology familiar, thanks to car manufacturers hard propaganda, even ordinary consumers are aware of a car body laser welding length reaches the number of meters. Indeed, laser processing technology as an advanced manufacturing technology in automotive applications greatly enhance the level of manufacturing cars, improve production efficiency and quality. However, with the development of technology, laser applications in the car and not limited to these processing areas.

Laser headlights: smaller, lighter, more energy-efficient

Car headlights on cars as an important component in providing illumination to ensure road safety also played a decorative role and aesthetics. Now, with the continuous development of technology, it is also hoped that it can be more bright, but also be more energy-efficient and durable. Thus, in the automotive industry a hundred years of history, car headlights also experienced a series of technical innovations, from the halogen headlights, xenon headlamps to today's LED headlamps. However, when the car manufacturers are still vigorously promote the various advantages of LED headlights,burning laser pointer headlights "grab" a great come from behind the trend.

Audi R8LMX Laser Headlights

It is understood that the first to propose the idea of laser technology for automotive headlamps are BMW and Sandia National Laboratories. They used blue, red, green and yellow light combine to create a light emitter produces a comparable ordinary white light source, but also a better solution to the laser diode laser hair white color rendering poor quality problems. In 2011, BMW will be the first laser headlamps applied i8 concept car, the car production models to the market in the autumn of 2014, becoming the world's first production car equipped with laser headlamps, followed in turn applied to the new BMW generation 7 Series models. At the same time, many achievements in the field of automotive lighting and Audi fans were dubbed the "Light Factory" natural to be outdone, has its matrix laser headlight technology is also used in R8LMX production car.

People will ask: LED headlamps already have energy saving, long life, small size, brightness, low attenuation and the corresponding speed, etc., why do you need it in fact laser headlights, the laser light source is different from ordinary light, it's just color? light source, only one wavelength of light, so this feature allows the laser light more brightness, light type can be accurately, quickly and safely control. Thanks to these characteristics, in addition to having the advantages of laser headlamps LED lights, the higher its brightness, LED headlamps is a thousand times, thus further irradiation, laser headlights BMW i8 models the effective radiation on the distance of up to 600 m; in addition the volume of 20000mw laser pen headlight assembly smaller, giving automotive designers design leaves more space; more importantly, higher lighting efficiency of the laser headlights, thus more energy efficient in the future depend advantage of battery-powered electric vehicle will become more apparent.

Laser Radar: the Development of Automatic Driving Vehicle

If the car is about to enter a new lighting era, the automotive industry is also another great era will come, and that is self-driving cars. Self-driving cars is the utilization of sensors and vehicle networking technology to collect vehicle and the vehicle surroundings data, onboard computer through these real-time data as the basis to judge to control the vehicle's acceleration, braking and steering systems in order to achieve the unmanned under a technology self-driving.

Google Automatic Car Driving Test

In real-time data collection, sensors mounted on the vehicle plays a very crucial role, these include a camera, radar and ultrasonic sensors. In fact, these technologies have been in today's vehicles widespread application for lifting traffic safety, such as lane keeping, the emergency braking system and reversing aids. However, these sensor technologies have advantages and disadvantages, in terms of any kind of automatic pilot technology can not meet the demand. And another for the Detection and Ranging technology - laser 5000mw radar applications in the car, and these sensors complement each other to speed up the implementation of self-driving cars.

Laser radar, also known as LIDAR (Light Detection and Ranging), based on the position of the emitted laser beam to detect targets, speed and distance and other characteristics of the system. It is understood that the laser radar originally used in the military field, as target detection and tracking system, is considered to be more difficult to detect enemy interference and devices. Unlike camera and ultrasonic sensors, laser radar data by reading the laser reflection can accurately determine the shape and position of the object, or even detect lane markers, potholes and slope, to achieve these data for the car is very autopilot important. In addition, since the laser beam long range, it can detect more distant objects, making the car can "see" farther.

On Google's autonomous vehicles, positioning navigation system will use a 64 laser technology for object detection and ranging, to collect more than one million data points of information, providing critical location information and navigation functions. In addition to Google, including Toyota, Volkswagen, BMW, Audi, Nissan and other companies as well as the mainland, including OEM, Bosch and Delphi and other first-tier suppliers, are developing and testing autonomous vehicles technology, in addition, Baidu's unmanned driving a car has also been tested on the road, these companies naturally also uses laser radar technology. In the foreseeable future, the development of self-driving cars will lidar create huge market demand.

Laser HUD: To Improve Traffic Safety

Head-up display (HUD), also known as HUD, in recent years the car has received more and more attention. The device information of the vehicle will travel by way of projection onto the front windshield, such as vehicle speed, engine speed, navigation information, as well as some oil warning information. HUD allows the driver of the vehicle in the process with eyes remain on the road ahead, do not looked down to see the information, thus helping to improve traffic safety.

Traditionally, the use of head-up display lamp as a light source directly reflected by the screen display data, the results show that with the quality of light and brightness of a great relationship. As the projector as a light source from HUD through the traditional light bulb turning to LED, laser 3000mw technology until today. The first laser HUD first appeared at the 2011 Consumer Electronics Show in Las Vegas, Audi and Pioneer showcased their technology.

Laser headlights, laser radar and laser HUD, which are have been used in the production model. However, laser technology in automotive applications is not limited to this, such as research institutions and have car manufacturers began to try a laser ignition system for an engine spark plugs improve combustion efficiency up; in addition to car manufacturers use laser gesture detection and ranging (equivalent to the foregoing principle of laser radar), for the gesture control system, the system of control. Looking to the future, with the advent of technology continues to evolve and new needs, the laser will play a greater potential to meet the demand for automotive safety, environmental protection and intelligent.